A Look Into the Workshop

= Mandonator™ Serial #7 ===

This instrument was commissioned by multi-instrumentalist Alan Bond.

The options he chose are:

- Five strings with 14.295" scale

- Bubinga back and sides with curly maple binding

- Mahogany neck

- Ebony fingerboard bound in curly maple

- Curvy, paddle shape headstock with bubinga veneer, bound with curly maple

- White mother-of-pearl diamond shaped fingerboard position markers

- White mother-of-pearl star inlay on headstock

- Nickel plated hardware

- Gotoh 510 Mini tuners

- Cast James tailpiece

- Radiused fingerboard

Standard features include:

- Spherically arched back

- Spider bridge and resonator cone

- Cutaway

- Traditional F-shaped soundhole

- Maple saddle

- Bone nut

The rims are bent and joined to the endblocks. The curly maple inlays are installed. The side braces and linings are in place.

Here is the back being assembled. It's being braced to about a 15-foot spherical radius. This allows the back to be more rigid and stronger for its weight, and it looks cool. The top is flat - there's so little wood on the top that arching it wouldn't add any significant strength.

Here the rims are being clamped to the back. The workboard under the back is dished to match the 15 foot radius spherical arching. The sack on top is a 25 lb sack of shot. The guy at the gun shop wondered why I didn't know one type of shot from another. I only cared how much the sack weighed!

Here are the three neck blanks I'm going to be working on again soon. I'll work on them sequentially. Pretty obvious which is which. Each person wanted a very different version of the neck, so I need to treat them separately in order not to confuse myself.

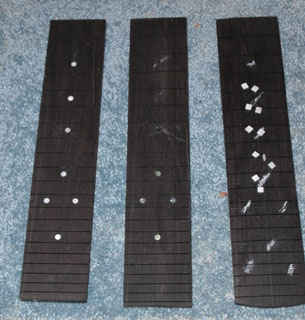

And here are the fingerboards. Left, Nokleberg (white MoP dots); middle, Hansen (abalone dots); right, Bond white MoP squares). There are three inlays missing from David Hansen's fingerboard. I must place an order for those dots right away! Hah! I thought I had enough. The chalk scores on Alan Bond's fingerboard are to remind me where to drill. Since the inlays are square, I will have to figure out what size drill to use, then chisel away the points of the squares.

The back is assembled to the rims, the binding ledges cut, and the binding installed. The next step will be to cut and drill the neck attachement mortise. The neck blank has its graphite truss rod installed and the neck attachment hardware and will soon have the tenon cut and the shape profiles cut. The fingerboard inlays are in and the binding is done. Next step is to install frets.

The neck is almost ready. After some more sanding, I'll attach it to the body, add the nut, hardware, and strings, and see how it sounds! At this point I can still adjust the shape of the neck somewhat for playability, if needed. Then it will be ready to go to Addam Stark for its lacquer finish

The neck is almost ready. After some more sanding, I'll attach it to the body, add the nut, hardware, and strings, and see how it sounds! At this point I can still adjust the shape of the neck somewhat for playability, if needed. Then it will be ready to go to Addam Stark for its lacquer finish

Mandonator™ 7 has been completed! You can see photos of the finished instrument on its Gallery page.